Headed Concrete Anchors and Shear Connector Weld Studs Selection Guide

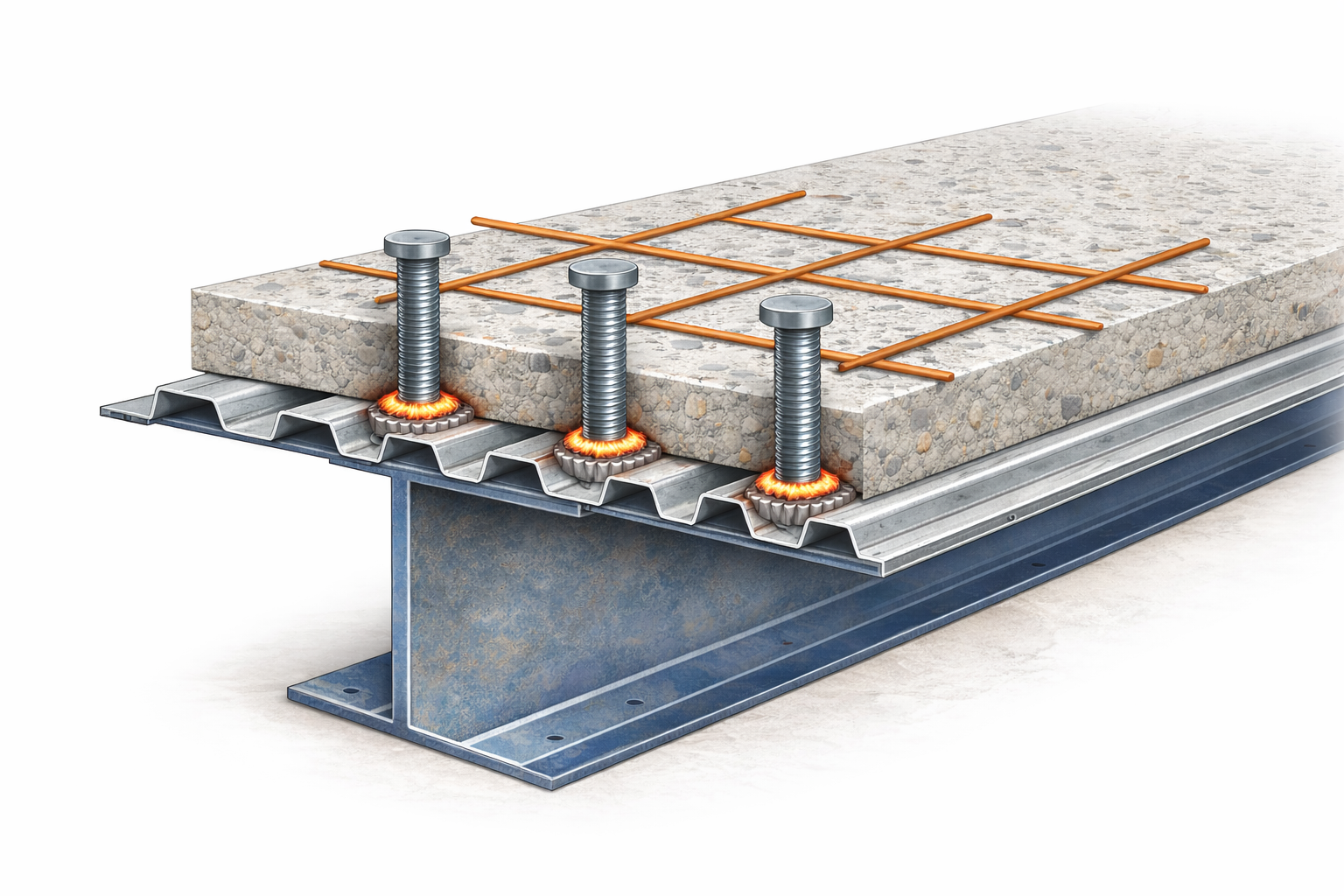

Headed concrete anchors, commonly referred to as shear connector weld studs, are used to transfer load between steel members and concrete in composite construction. These studs are welded to structural steel and embedded into concrete slabs, panels, or decks to create a composite structural system.

What Headed Concrete Anchors Do

In composite construction, headed concrete anchors prevent slip between steel and concrete by transferring shear forces across the interface. This load transfer allows steel beams and concrete slabs to act together structurally, increasing strength and stiffness.

Headed concrete anchors are commonly installed using drawn arc stud welding to ensure consistent fusion and predictable performance.

Common Applications

- Composite steel and concrete floor systems

- Bridge decks and civil infrastructure

- Precast concrete panel connections

- Tilt up wall construction

- Structural beams, columns, and embed plates

Selecting Stud Diameter and Length

Stud diameter and length are selected based on load requirements, slab thickness, and required embedment depth. Larger diameters provide higher shear capacity, while stud length must account for concrete cover and welding requirements.

- Diameter selection is driven by required shear capacity

- Length must allow for proper embedment into concrete

- Project specifications and engineer requirements govern final selection

Materials and Finishes

Headed concrete anchors are commonly manufactured from low carbon steel for structural applications. Stainless steel options are available for environments requiring corrosion resistance.

- Carbon steel for general structural use

- Stainless steel for corrosive or exterior environments

- Material selection should align with project specifications

Applicable Codes and Standards

Most headed concrete anchor installations reference industry standards to ensure safety and performance.

- AWS D1.1 for stud welding procedures

- ACI 318 for concrete anchorage design

- ASTM A108 for material and dimensional requirements

Installation Overview

Headed concrete anchors are typically installed using drawn arc stud welding equipment. Proper surface preparation, ferrule selection, and equipment setup are critical to achieving consistent weld quality.

- Clean base material prior to welding

- Use correct ferrule matched to stud diameter

- Follow equipment manufacturer setup guidelines

Product Availability

Eugene Fastener stocks headed concrete anchors and shear connector weld studs in multiple diameters, lengths, and materials to support fabrication shops and job site requirements.

View available products here: Headed Concrete Anchors and Shear Connector Weld Studs